News

More

(1) Laser power input power: three-phase four-wire system 380V± 5% Power rated power: 10KW pulse working current: 0-400A Power instability: ≤± 5% (2) Laser laser wavelength: 1.06μm Laser working material: Nd:YAG crystal Maximum output energy: 60J

Brand:

Model:

- Introduction

- Technical

- System

- Service

- Message

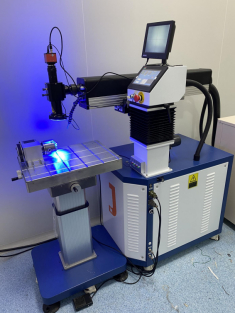

Laser precision welding machine

(1) Laser power supply

Input power supply: three-phase four-wire system 380V± 5%

Rated power: 10KW

Pulse working current: 0-400A

Power supply instability: ≤± 5%

(2) Laser

Laser wavelength: 1.06μm

Laser working material: Nd:YAG crystal

Maximum output power: 60J

Average power: 200W

Pulse frequency: 1-100Hz

Pulse width: 0.1-10ms

Beam divergence Angle: ≤10mrad

Energy instability: ≤ 5%

Continuous working time: 16h

(3) Cooling system

The laser adopts full cavity circulation water cooling mode, the inner circulation cooling medium is deionized water or pure water, and the outer circulation is cooled by refrigeration unit.

The cooling system consists of water tank, heat exchanger, filter, magnetic pump, water temperature sensor and water pressure relay.

Temperature control range: 10-350c

Temperature stability: ± 10c

Fault protection: undercurrent protection and overtemperature protection interlocking with laser power supply

Water purity: >0.5MWcm

Cooling power: 2P

When the water flow is less than the set value or the temperature is greater than the set value, the laser will automatically stop working.

(4) Laser indicating positioning system

The semiconductor laser is used as the indicator light source, which is used as the adjustment reference of the optical system and the indication positioning of the working point.

(5) external optical path light guide system

Laser focusing objective working distance :75mm

Laser focus spot size: 0.3-0.6mm

(6) Workbench

According to welding needs, X, Y axis two-dimensional precision table is used, the table is controlled by PLC. To meet customer use.

Step equivalent: 0.01mm

Reset accuracy: 0.025mm

(7) Gas protection device

According to the welding needs, a set of gas blowing system is adopted to configure coaxial and side-axis blowing to ensure the welding package effect.

(8) Monitoring system

Equipped with a 14-inch black and white monitoring system with a magnification of 20 times, you can easily observe the effect and alignment before and after welding.

- Contact

- Tel:027-87024316

- 18901354771

- 18901354771