News

More

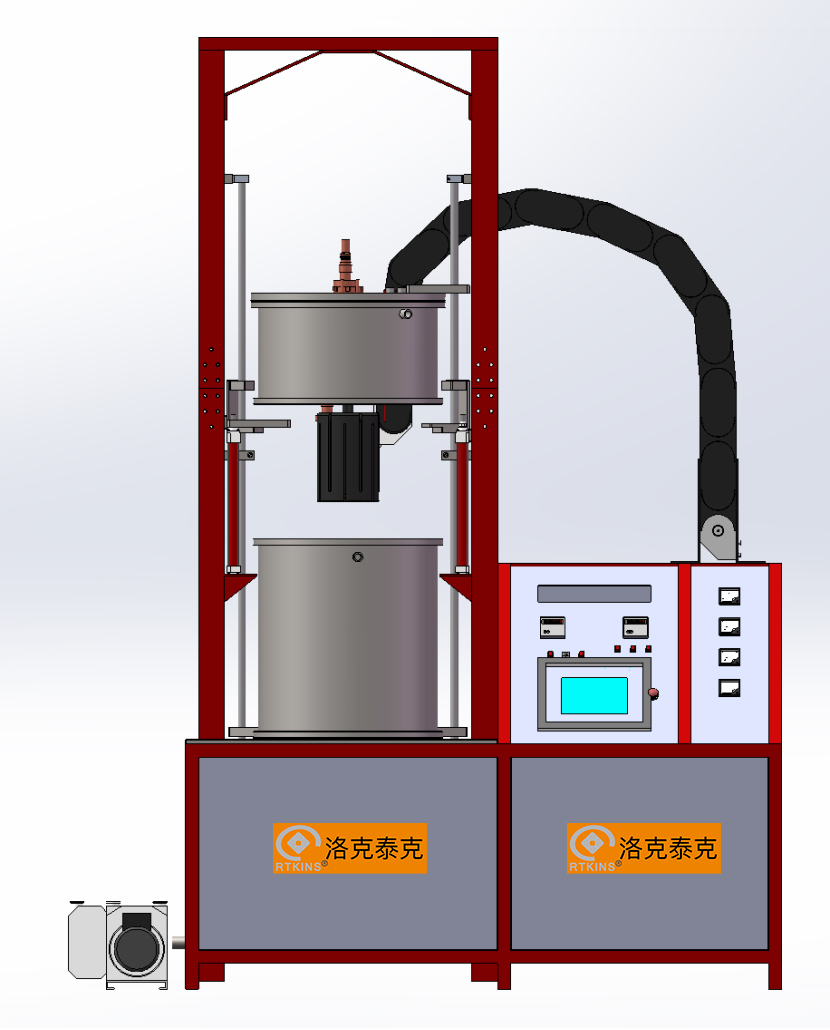

Rotary atmosphere sintering - Centrifugal sintering furnace

Mainly used for rotational heat treatment of experimental samples. Adopting an industrial computer and high-performance hybrid logic controller to achieve manual and automatic process control and monitoring, it has high control accuracy, good reliability, and easy maintenance.

Brand: Rocktek

Model: 旋转气氛烧结-离心烧结炉

- Introduction

- Technical

- System

- Service

- Message

Ø The furnace wall, upper and lower flanges, copper electrodes, and cables are all cooled by circulating water cooling.

Ø Automatic control of human-machine interface/on-site manual operation. Using professional industrial control software, we provide users with a powerful and user-friendly monitoring window through design and configuration. The system can collect and record real-time working data such as temperature and vacuum degree of the equipment, generate operation logs, and save them. It can be queried, analyzed, operated, and played back on the industrial computer. The operating system can achieve independent multi-channel and multi-stage PID adjustment control and monitoring of temperature, and can complete functions such as editing, debugging, and storage of temperature control curves. The process curve can be stored in both the control programmer and the hard drive of the industrial control computer through configuration software to avoid the loss of process data. Equipped with power on cumulative timing function.

Ø Max temperature:2100℃, which can be used for a long time at 2000 ℃. Temperature control: Zone 1 control, with an adjustable heating rate of 0-20 ℃/min, a pressure rise rate of ≤ 0.65 Pa/h, and a working vacuum of ≤ 30 minutes.

Ø Loading method:Vertical lifting

Ø Over temperature and power outage protection

Ø Cage type graphite heater. The heater can be raised during material retrieval.

Ø The furnace wall, upper and lower flanges, copper electrodes, and cables are all cooled by circulating water cooling.

Ø Automatic control of human-machine interface/on-site manual operation. Using professional industrial control software, we provide users with a powerful and user-friendly monitoring window through design and configuration. The system can collect and record real-time working data such as temperature and vacuum degree of the equipment, generate operation logs, and save them. It can be queried, analyzed, operated, and played back on the industrial computer. The operating system can achieve independent multi-channel and multi-stage PID adjustment control and monitoring of temperature, and can complete functions such as editing, debugging, and storage of temperature control curves. The process curve can be stored in both the control programmer and the hard drive of the industrial control computer through configuration software to avoid the loss of process data. Equipped with power on cumulative timing function.

The furnace wall, upper and lower flanges, copper electrodes, and cables are all cooled by circulating water cooling.

Automatic control of human-machine interface/on-site manual operation. Using professional industrial control software, we provide users with a powerful and user-friendly monitoring window through design and configuration. The system can collect and record real-time working data such as temperature and vacuum degree of the equipment, generate operation logs, and save them. It can be queried, analyzed, operated, and played back on the industrial computer. The operating system can achieve independent multi-channel and multi-stage PID adjustment control and monitoring of temperature, and can complete functions such as editing, debugging, and storage of temperature control curves. The process curve can be stored in both the control programmer and the hard drive of the industrial control computer through configuration software to avoid the loss of process data. Equipped with power on cumulative timing function.

- Contact

- Tel:027-87024316

- 18901354771

- 18901354771